Chemona

Chemona was founded in 2009 through a collaboration between Thomas Allart and a Nanocoating manufacturer in Germany. Thomas had been using the products himself since they became available on the European market.

Originally licensed in the Benelux countries, in 2014 Chemona registered its name world-wide and began to develop an international network of importers, distributors and dealers. New products are developed and added to the line in response to the needs of applicators and distributors under the name and technical expertise of Chemona. All Chemona coatings are manufactured in The Netherlands and Germany.

Development, quality and safety

Different markets have different needs. Chemona works closely with its partners to make sure the correct coating is specified for each application, and if necessary to develop a new coating for a particular project. These coatings are tested in house and at third-party labs.

Safety is paramount – both in application and in the end use. In 2012 Chemona began working with the Nano-Next institute at TNO, the Netherlands Organisation for applied scientific research. TNO tests all of Chemona’s coatings for safety and efficacy. This relationship has yielded a large volume of data which is used to generate safe handling guidelines for applicators and consumers.

In addition, Chemona works with TUV Rhineland to certify corrosion resistance, UV resistance, slip coefficient, and adhesion norms. These results are included in the product details pages or can be requested directly.

Partners

Chemona is a member of the Association of Paint and Printing Ink Manufacturers (VVVF).

Certified applicators & training

Most of Chemona’s coatings are easy to apply and suitable for the consumer market. However, certain applications are most suited to professionals with the knowledge and expertise to ensure a superior result. Professional applicators can be trained by our team at our facilities or on-site.

Chemona offers a wide range of coatings all based on the same nanotechnology. However, different coatings are preferred for different surfaces. After the training module the trainee know exactly which products are suitable for which surfaces and how to pre-treat, treat and maintain a surface with Chemona.

The certified applicator will receive a testkit for samples and gain access to our network of projects and industry experts to help them develop new business.

Nanotechnologie

Nanotechnology is a general name. It refers to applications and techniques that work on a scale of 1 to 100 nanometers. A nanometer is a billionth meter. Nanotechnology works at the level of molecules and atoms.

The lotus effect of nanotechnology

Nanotechnology makes many new applications possible and is therefore called an enabling technology. It gives the possibility to surround even the smallest particles of atoms with a dirt and water repellent protective layer. Because of their tiny size nanoparticles adhere to nearly any surface and essentially displace larger particles like water, dirt or oil. This displacement means that foreign substances no longer have the ability to attach themselves to the surface, yielding an ultra-thin, invisible and undetectable protective layer with an extremely long life.

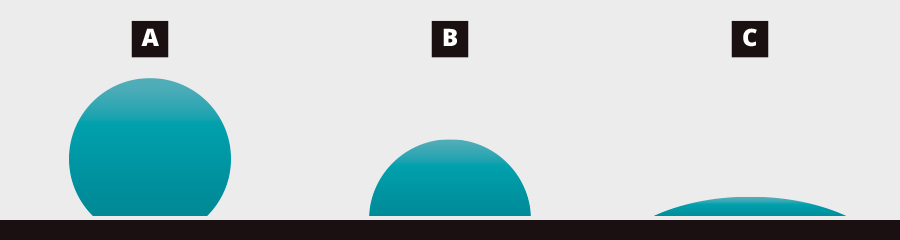

The effect of Nanotechnology is also called lotus effect, because the leaves of the lotus flower keep themselves clean and are insensitive to moisture and dirt in the same way. The lotus effect is caused by the surface being water-repellent. This effect is illustrated below.

- Normally a drop of water flows over the surface as shown in figure C. The surface is then hydrophilic (not water-repellent)

- If the material is water-repellent (hydrophobic), the drop will make as little contact as possible with the surface. The drop will largely retain its shape as in figure B.

- If the material is treated with nanocoating, the surface becomes extremely water-repellent and the lotus effect is created. The droplet makes minimal contact with the surface and remains round as in figure A.