In industrial and technical environments, machines are subject to influences on a daily basis that can negatively affect their appearance and operation. Think of dirt, dust, grease, oils, chemical vapours and UV radiation. Over time, these factors cause discolouration, weathering of paint layers and damage to the surface. This makes maintenance more intensive, the appearance less professional and can ultimately even shorten the lifespan of the machines.

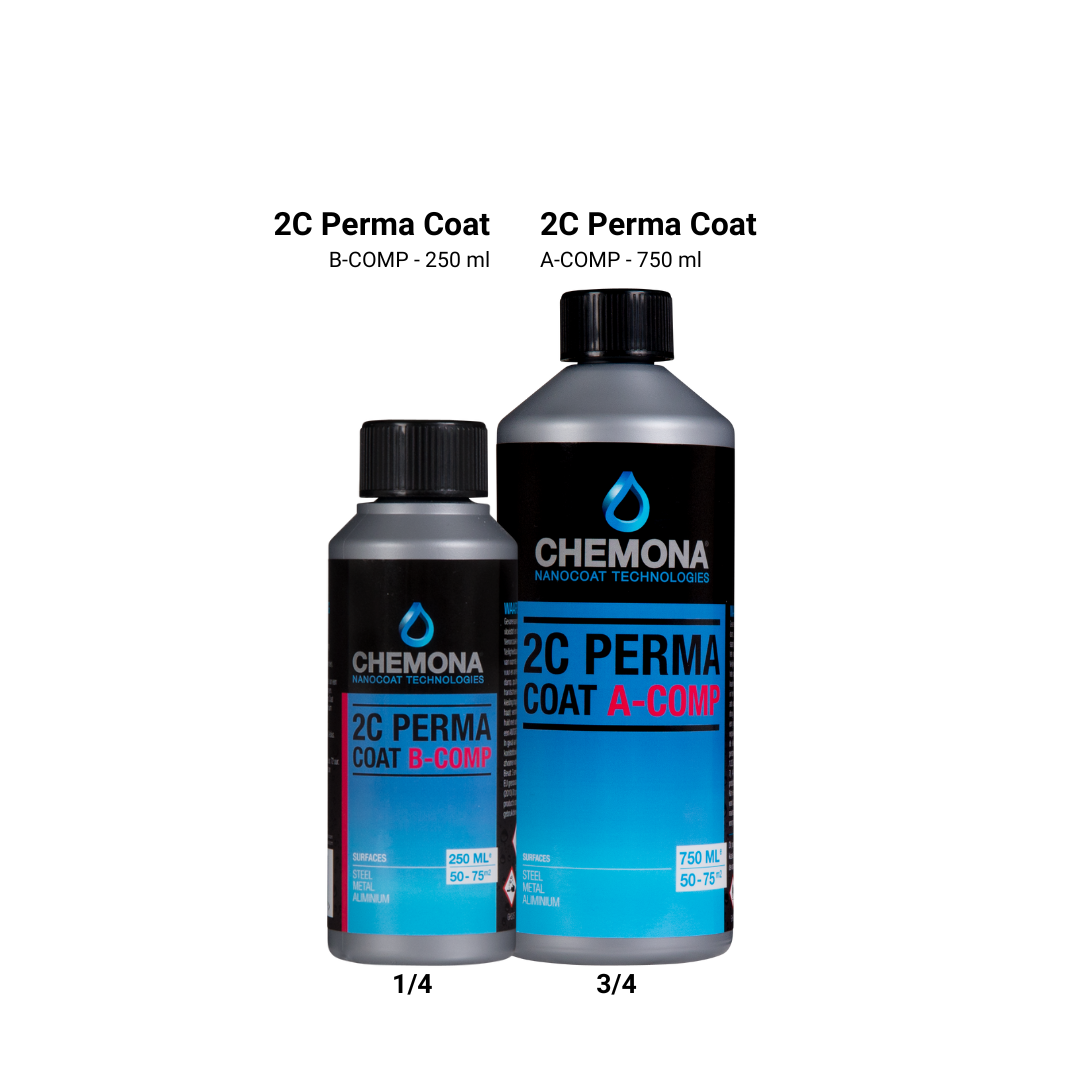

To counteract this and to optimally protect machines, 2C Perma Coat Gloss was chosen. This high-quality, two-component coating offers long-lasting, glossy protection and forms a wear-resistant, dirt-repellent top layer that is easy to clean. Thanks to its chemical composition, the coating adheres excellently to various surfaces and continues to perform reliably even under difficult conditions.

Purpose and benefits of the application

The application of 2C Perma Coat Gloss is part of a broader strategy to keep the machines in top condition, both functionally and visually. The benefits are manifold:

- Long-term protection against external influences: The coating seals the surface against moisture, dirt, oil and other contaminants. This prevents deterioration, corrosion and structural damage.

- UV resistance: Machines that are (partly) outside or exposed to natural light retain their colour and gloss for longer thanks to the UV-resistant properties of the coating.

- Improved cleanability: The smooth, glossy surface ensures that dirt adheres less quickly and is easy to remove. This reduces cleaning costs and saves time in the maintenance process.

- Professional appearance: Clean, shiny machines give a well-groomed impression to customers, visitors and inspection authorities. This contributes to the image of the company as professional and maintenance-oriented.

- Higher residual value: When machines are sold or traded in, their appearance has a major influence on their value. A machine that is well maintained and treated with a protective layer will be more attractive on the second-hand market.

- Sustainable and environmentally conscious: By extending the life of existing machines, the need for replacement is reduced. This saves resources and reduces the company's ecological footprint.

Areas of application

2C Perma Coat Gloss is suitable for a wide range of applications, including:

- Production machines in factories and workshops

- Construction and agricultural machines

- Transport and logistics equipment (such as forklifts or internal transport equipment)

- Electrical installation or equipment housings

- Metal or plastic machine covers and panels

The coating can be applied both preventively and restoratively, for example on machines that are already discoloured or whose original paintwork has been damaged. The treatment is part of a sustainable maintenance strategy that focuses on preservation, protection and appearance.

By using 2C Perma Coat Gloss, a company not only invests in protection against wear, dirt and ageing, but also in preserving the value, reliability and presentation of their machines. The coating contributes to a more efficient maintenance process and keeps machines looking representative for a long time, regardless of the conditions in which they operate.